Streamline Gemba Walks with a Digital Checklist

A gemba walk is when leaders and managers head to the “gemba” — the actual place where work happens — to observe processes, talk to employees, and spot opportunities for improvement.

It’s a core lean practice that helps organizations connect leadership with frontline work and encourage problem-solving.

The challenge with traditional gemba walks is that they can be unstructured and inconsistent — notes get lost, and issues are not properly recorded. In the end, manufacturers simply do not follow through with required changes.

Going digital solves all of the major pain points. By using a mobile-friendly gemba walks checklist, the process becomes more efficient, standardized, and impactful. It makes it easy to log findings in real time — leaving managers with a clean record they can act on.

What is a gemba walk checklist?

A gemba walk checklist is a simple tool that helps managers and supervisors stay focused during a walk. It provides structure and ensures that key areas — like safety, quality, or employee engagement — are reviewed consistently every time.

Some organizations do gemba walks daily, while others do them weekly or monthly. The frequency depends on how quickly issues arise and how critical the process is.

Using a digital gemba walk checklist template instead of pen and paper enables teams to capture data in real time with photos or voice-to-text, providing richer context than handwritten notes. Managers get instant visibility into what was observed, and issues can be tracked, assigned, and reported without extra steps.

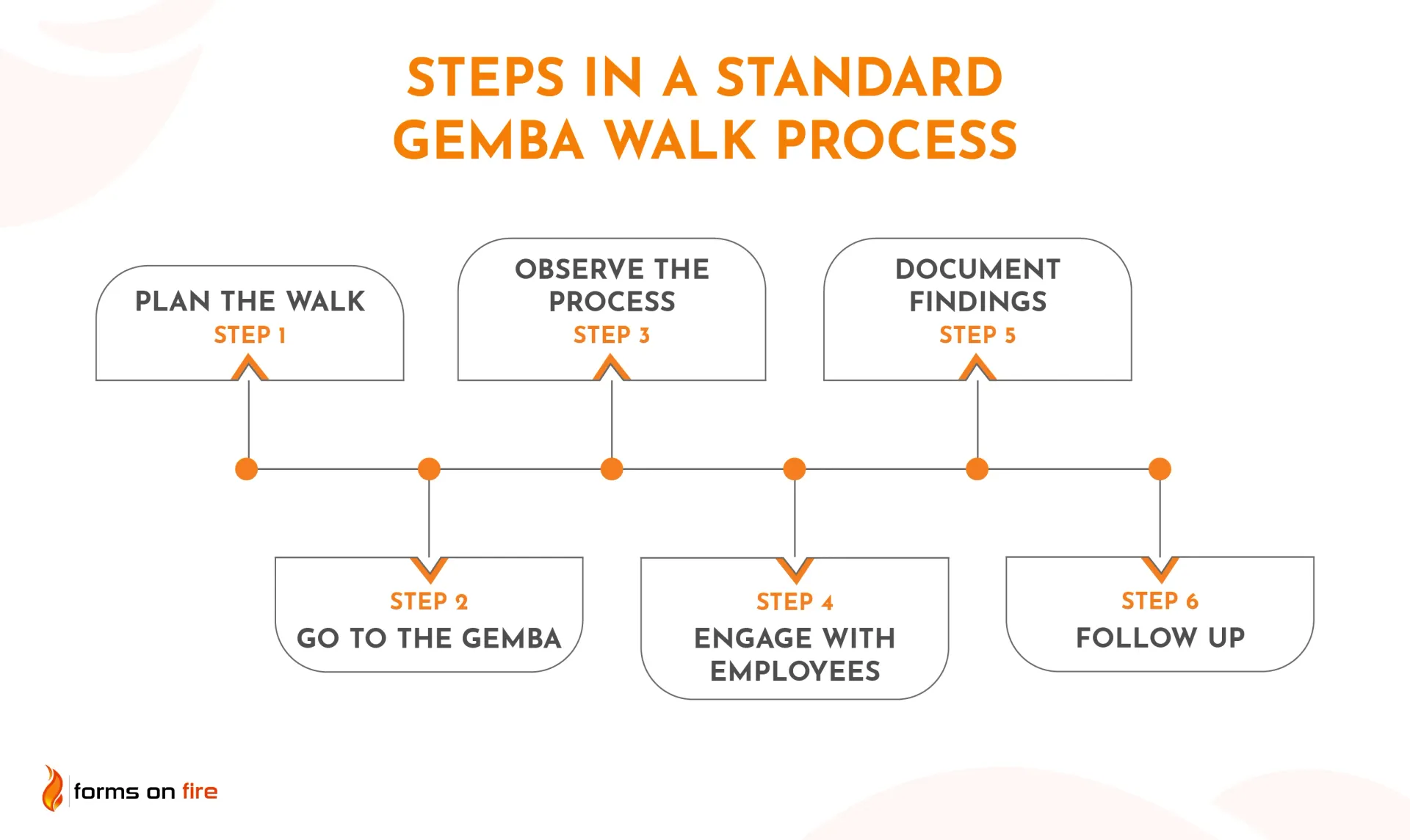

Steps in a standard gemba walk process

Here are the typical steps for conducting an efficient gemba walk:

- Plan the walk: Define the purpose (safety, quality, productivity, etc.) and decide which area (packaging line, assembly area, maintenance shop) you’ll focus on.

- Go to the gemba: Visit the actual workplace where value is created.

- Observe the process: Watch how work is being done, without interrupting. Look for alignment with standards and areas where waste or risks are likely to appear.

- Engage with employees: Ask open-ended questions, listen actively, and encourage feedback. The goal is to understand the “why” behind what you just observed.

- Document findings: Write notes, take photos, or capture audio when you spot anything worth documenting. Using a digital form makes this step way easier.

- Follow up: Review observations with the team, assign actions, and track progress.

💡 Tip: Before you start a gemba walk, make sure you understand the process you’re about to observe. If you’re unfamiliar with how the work is supposed to flow, it’s easy to misinterpret what you’re seeing. A little preparation — like reviewing standard work documents or talking with a supervisor beforehand — will make your observations more accurate and useful.

What to include in your gemba walk checklist for manufacturing

There are a lot of moving parts on the plant floor. If you try to cover everything at once, you’re either going to miss important observations or take ages to finish the walk. Instead, define and focus on the specific purpose of the walk.

For example:

- Safety walk → Focus on hazards, PPE usage, machine guarding, emergency exits.

- Quality walk → Focus on standards, inspection methods, defect prevention.

- Productivity walk → Focus on bottlenecks, waste, mistakes, material flow.

- Employee engagement walk → Focus on communication, morale, training needs.

Recommended fields to include in your gemba walk checklist template:

- Date & time: Keeps a record of when the walk was performed.

- Area/department: Identifies the physical location being observed.

- Type of walk: Safety, quality, productivity, or engagement.

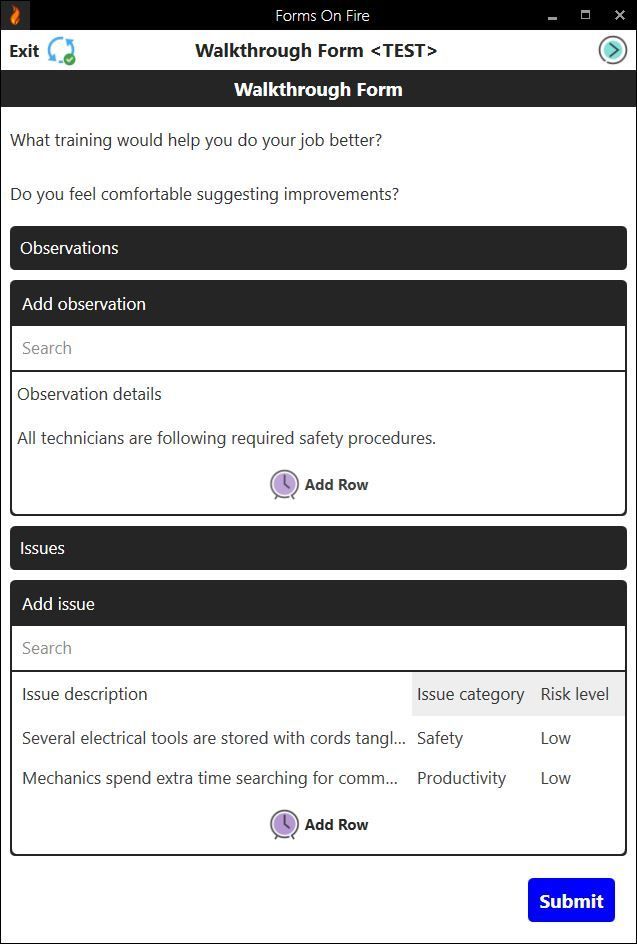

- List of common questions to ask: Is there an established process for this type of work? Is there anything slowing you down or making the job harder? Do you have ideas for how this process could be improved? Do you have the tools and training you need? Who do you speak to if you encounter a problem? And similar.

- Observations: Space for notes, voice-to-text, photos, or even videos.

- Issues found: A list of identified problems that need attention.

Optional fields you can include:

- Risk level: Tag issues as low, medium, or high priority.

- Responsible person: Assign each issue to a person or team who will be accountable for implementing needed corrective actions.

Digital forms make these fields easy to customize, so you’re not locked into one rigid template. You can build a template for each type of Gemba walk you are performing regularly.

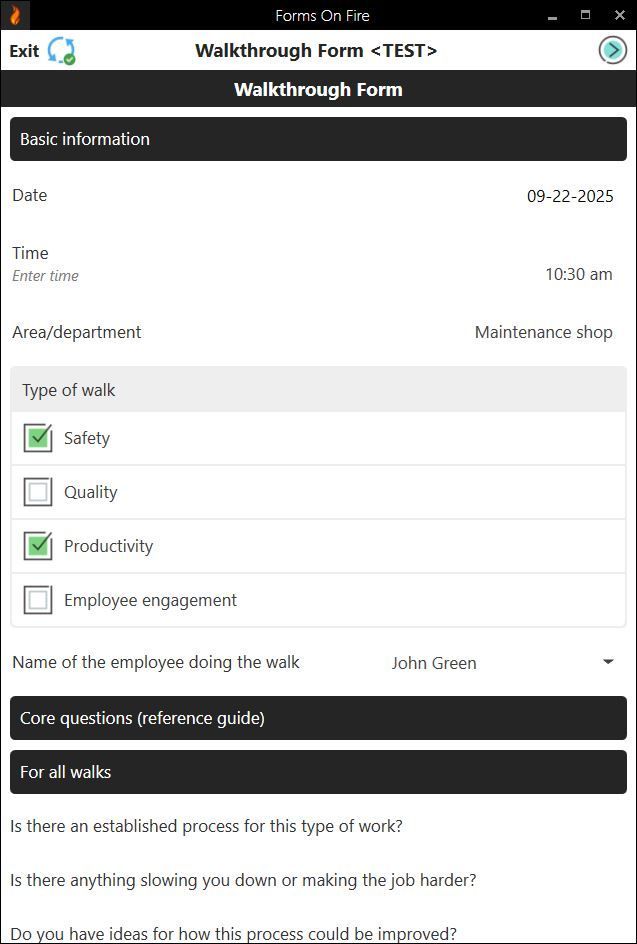

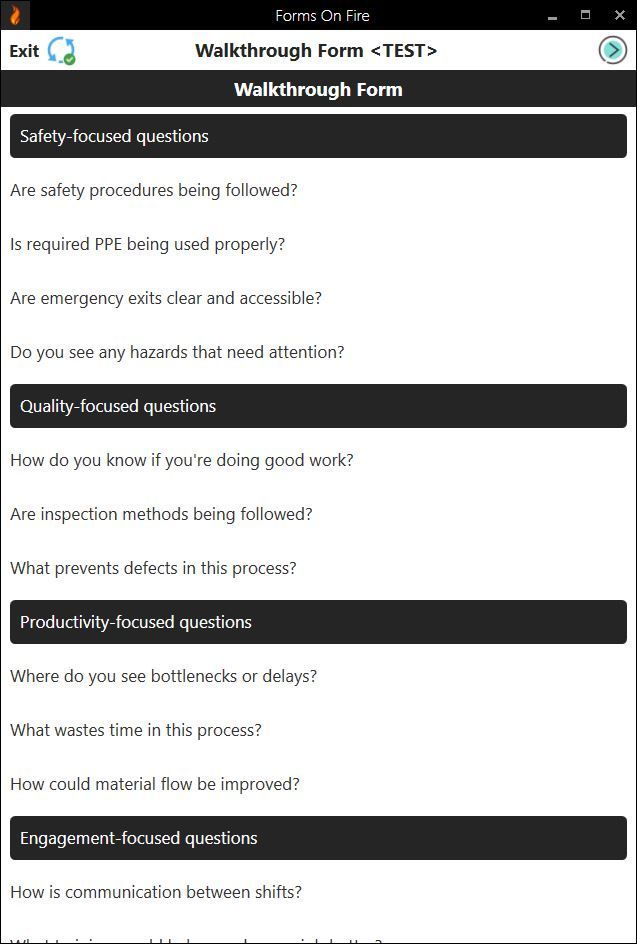

An example of a digital gemba walk checklist

Here is an example of a gemba walk checklist built using our no-code forms builder called Forms On Fire.

This template is fully customizable — you can add or remove fields depending on the purpose of the walk. For example, you can leave only the questions related to productivity or safety, add categorizations for observations, or expand the issues section by including a “Responsible person” column.

And if you are worried that these forms won’t work because internet connectivity is weak on your plan floor — don’t be; our forms work offline, and sync everything as soon as you acquire a stable internet connection.

Tips for structuring questions you plan to include

When building a gemba walk checklist, the way you frame your questions matters. Here are some best practices to keep in mind:

- Keep them simple: Short, clear questions prevent confusion and speed up the walk.

- Use open-ended prompts: Encourage employees to share insights instead of just “yes/no” answers.

- Organize by theme: If you are trying to cover more themes at once, group safety, quality, productivity, and engagement questions so the checklist flows naturally. Otherwise, only include questions tied to the specific purpose of the walk to avoid overload.

- Keep core questions consistent: Standard questions across all walks make it easier to track trends and compare findings over time.

- Add situational questions: If needed, feel free to rotate in items tied to current projects, goals, or previously found issues.

- Use lean principles as a guide: If you do not know where to start, frame questions around value, waste reduction, and continuous improvement.

Build your own gemba walk checklist template with Forms On Fire

There’s no universal checklist you can just download and use for any and every situation. The right questions depend on your processes, your goals, and the issues you’re working on right now.

That’s why the most effective approach is to build your own template — and adjust it as things change.

With Forms On Fire, you can do exactly that. Our drag-and-drop form builder makes it easy to create a digital gemba walk checklist in minutes. You can start with our pre-made template and customize it to fit your operations. As your needs evolve, you just need to update one template, and everyone is going to see the newest version.

Other benefits of using Forms On Fire:

- Forms you make work offline, so you can use them anywhere.

- The platform is secure and compliant with the latest data protection standards.

- Forms On Fire can integrate with almost any manufacturing, maintenance, or ERP systems for seamless reporting.

- You will get instant access to hundreds of other templates in our database, which you can use to streamline safety audits, inspections, incident reporting, and more — across a variety of industries.

👉 Start your free trial today and get a customized gemba checklist that works for your team.