Crane Inspection Checklist

A comprehensive crane inspection checklist is a great tool for streamlining inspections and upholding the highest standards of crane performance and maintenance.

Click on the button below to start a free trial of Forms On Fire and get instant access to our checklist database which includes a crane inspection checklist template.

Let’s explore the practicalities of a crane inspection checklist — its purpose, the professionals who utilize it, the key aspects it covers, and how to create one that matches your operational requirements.

What is a Crane Inspection Checklist?

A crane inspection checklist is a structured tool used to ensure the safety and operational integrity of cranes. Its primary purpose is to systematically and proactively assess various aspects of crane equipment, identifying potential issues before they lead to accidents or equipment failure.

It is important to periodically inspect cranes due to the high risks associated with crane operations. These checks should be aligned with major inspection requirements, including those set by the Occupational Safety and Health Administration (OSHA).

OSHA guidelines will vary depending on which crane type is used. For example, for Cranes and Derricks in Construction, they state how to handle inspections after equipment repairs, the minimum requirements for daily inspections, and so on. Similarly, they have separate guidelines for overhead and gantry cranes used in material handling.

Who Uses Crane Inspection Checklists?

Crane inspection checklists are essential in, well, any business or industry that operates cranes. These include, but are not limited to: construction, manufacturing, and shipping and logistics.

Within these industries, the checklists can be useful for:

- Safety inspectors

- Crane operators

- Maintenance personnel

- Site managers

The checklists are essential tools in these sectors, helping to uphold safety standards and ensure the smooth operation of these heavy pieces of equipment.

What Does the Crane Inspection Checklist Usually Cover?

A crane inspection checklist can accommodate various types of cranes, each with its specific set of requirements.

Common crane types include tower cranes, mobile cranes, and overhead cranes. Since there are significant differences between different cranes, like those used in construction vs those used in a warehouse, the checklist should be tailored to its respective crane type. It is the only way to ensure all relevant aspects are thoroughly covered.

When part of a comprehensive preventive maintenance program, most crane inspections will fall into one of these three categories: daily, weekly, and/or monthly crane inspection checks.

Daily checks usually cover:

- Operational controls

- Emergency stop functionality

- The structural integrity of visible parts

- Hydraulic systems and fluid levels

- Safety and warning labels

Weekly and monthly checks focus on:

- In-depth inspection of structural components

- Wire rope and hoist condition

- Load tests

- Electrical systems and connections

- Long-term signs of wear and tear

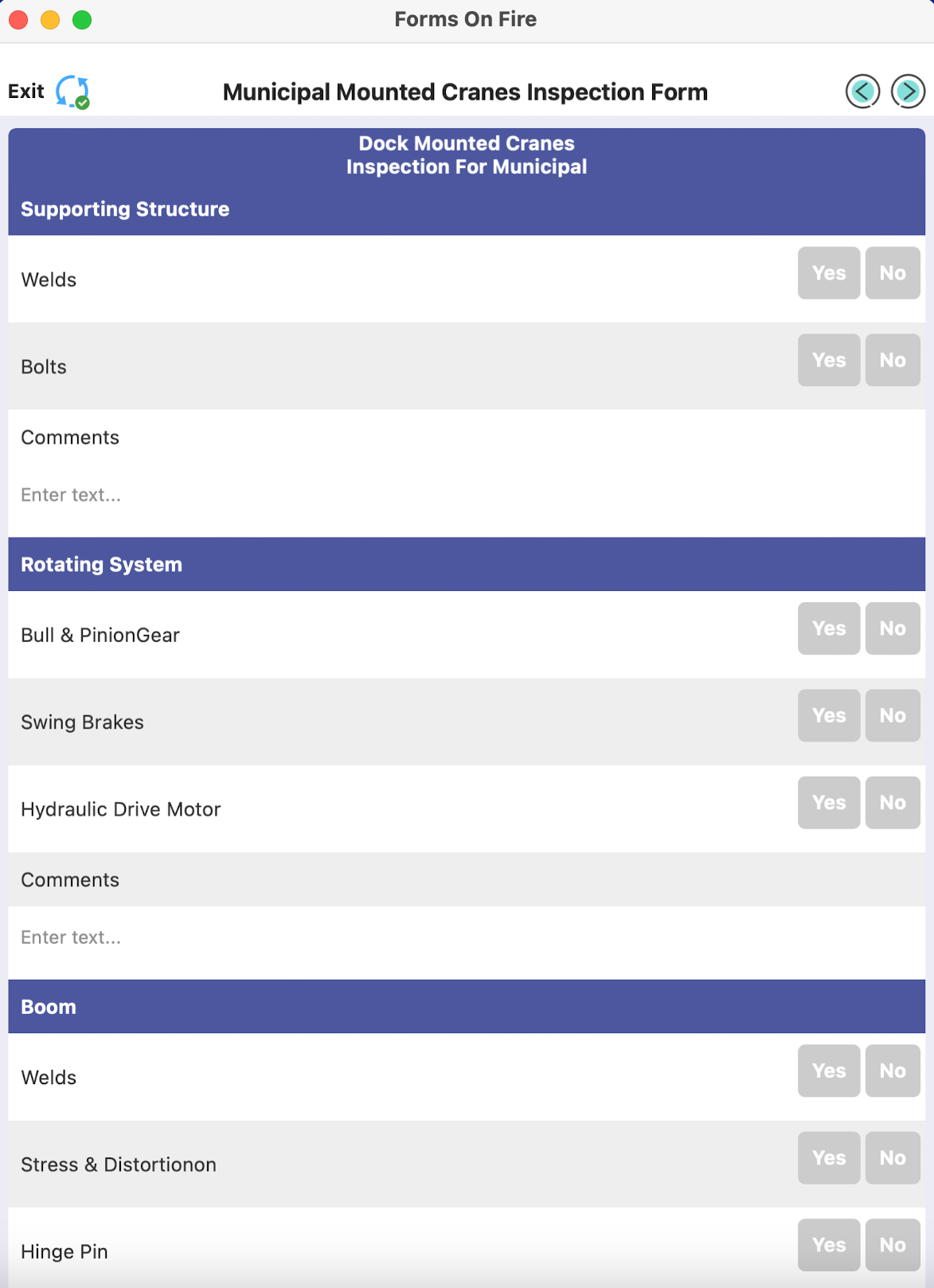

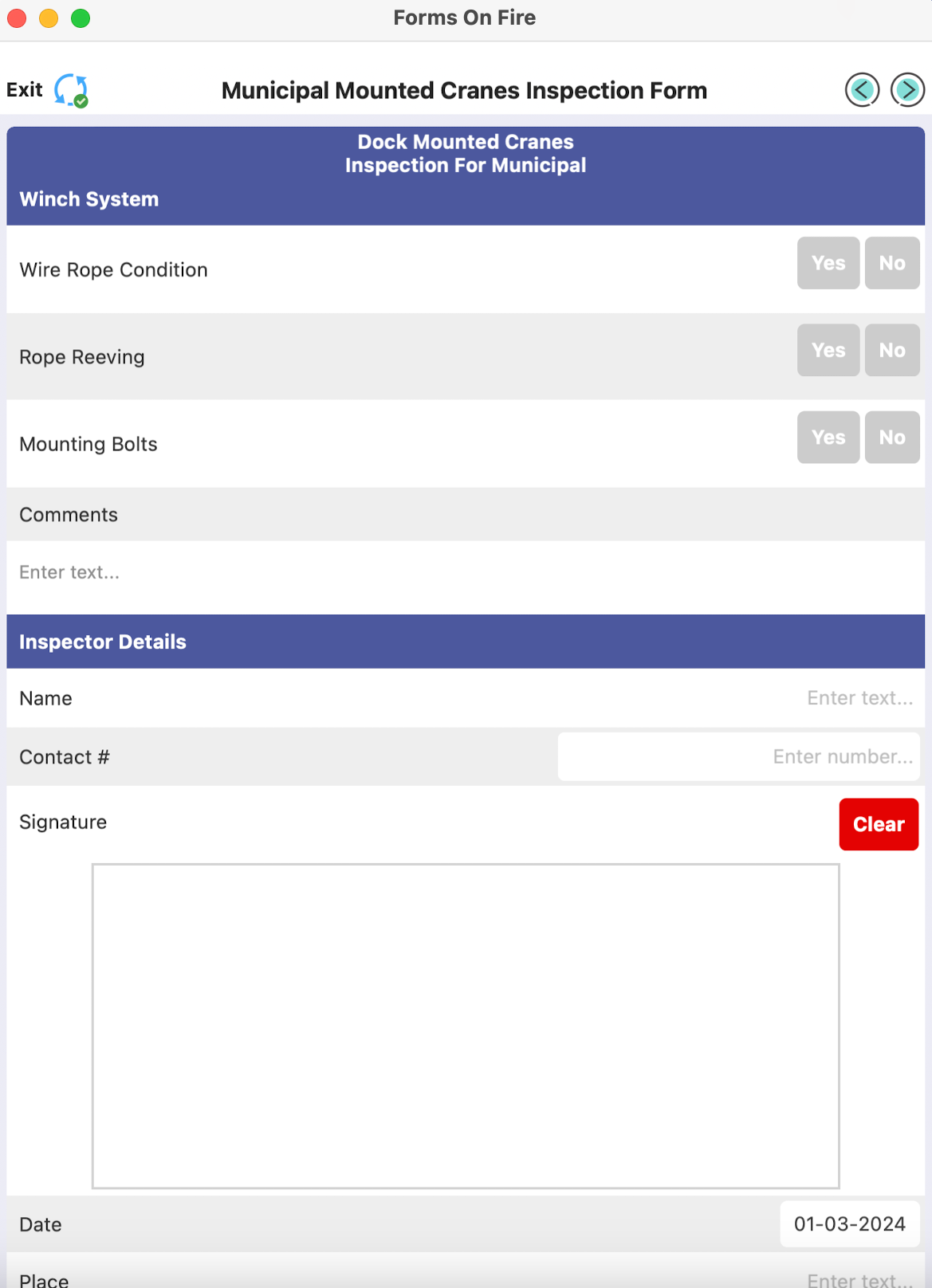

So, a typical crane inspection checklist with include some of the checks mentioned above, as well as feature administrative fields like:

- The name of the person performing the inspection

- Date and time of the performed inspection

- Comments/submission notes sections

This comprehensive approach ensures each crane is consistently evaluated for safety and operational efficiency, adapting to the unique features of different crane types and the environmental conditions they operate in.

Below, you can find a snapshot of a crane inspection from built using Forms On Fire for a dock-mounted crane.

Where Do I Get a Crane Inspection Checklist?

Forms On Fire offers a versatile range of customizable form templates, including crane inspection checklists. These templates can be conveniently published and shared with team members, who can then complete and submit them using mobile devices.

The platform also facilitates creating detailed reports from checklist data, simplifying equipment condition tracking and potential safety audits. This also eliminates the need for physical paperwork and repetitive manual data entry which is prone to error.