Get a Workplace Safety Inspection Checklist

Regular workplace safety inspections are your first line of defense against incidents that can hurt people and your business.

Safety officers utilize these checklists to stay vigilant about hazards across various work areas. Facility managers rely on them to catch maintenance issues before they become safety problems. HR teams need the documentation for training and compliance.

Practically anyone responsible for keeping people safe at work benefits from having a streamlined inspection process, supported by a digital workplace safety checklist.

Do not want to build one from scratch? Forms On Fire provides professionally designed safety inspection templates that you can easily customize to fit your specific workplace needs and regulatory requirements. You can start a free trial below to access the template:

Below, we'll show you precisely what to include in a workplace safety checklist and how digital tools can simplify the whole process.

What should a workplace safety inspection checklist include?

Safety officers and supervisors use workplace safety inspection checklists during routine inspections, safety audits, or post-incident evaluations. Companies increasingly use digital checklists on phones or tablets to simplify inspections and keep accurate records.

Depending on the industry and work environment, a workplace safety inspection checklist might include:

- General housekeeping: Check if walkways are clear of obstructions, spills are promptly cleaned up, and work areas are organized. Ensure trash and debris are properly disposed of and storage areas are neat and accessible.

- Emergency preparedness: Verify that emergency exits are clearly marked and unobstructed. Check if fire extinguishers are properly mounted, tagged, and up to date. Ensure first aid kits are stocked and accessible.

- Electrical safety: Inspect wiring for fraying or damage. Check if outlets are properly grounded and not overloaded. Confirm electrical panels are labeled and accessible, with no exposed wiring.

- Personal Protective Equipment (PPE): Verify that appropriate PPE is available for each job task. Check that safety equipment is in good condition and employees are using it correctly. Confirm that PPE matches the specific hazards of each work area.

- Ergonomics: Assess workstations for proper setup to prevent strain and injury. Check desk and chair heights, lighting adequacy, and repetitive motion risks. Ensure lifting equipment is available when needed.

- Chemical safety: Verify that all chemicals are properly labeled and stored according to Safety Data Sheets (SDS). Check if hazardous materials are in appropriate containers and storage areas have proper ventilation.

- Machinery and equipment: Inspect equipment for proper guarding and safety devices. Verify that maintenance schedules are up to date and lockout/tagout procedures are being followed. Check that operators are properly trained.

The exact items to include in your workplace safety checklist will depend heavily on your specific industry, work environment, and the types of hazards your employees face daily.

For example, a manufacturing plant's safety checklist would focus heavily on machinery guarding, noise level monitoring, chemical storage protocols, fall protection systems, and PPE compliance for hard hats, safety glasses, and steel-toe boots.

On the other hand, an office environment would emphasize ergonomic workstation setup, proper lighting, emergency evacuation procedures, slip-and-fall prevention, and electrical safety around computer equipment. There will be less need for industrial-grade protective equipment, but more attention to indoor air quality and repetitive strain injuries.

Workplace safety checklist template

With Forms On Fire’s no-code platform, you can build almost any digital form or app you can think of.

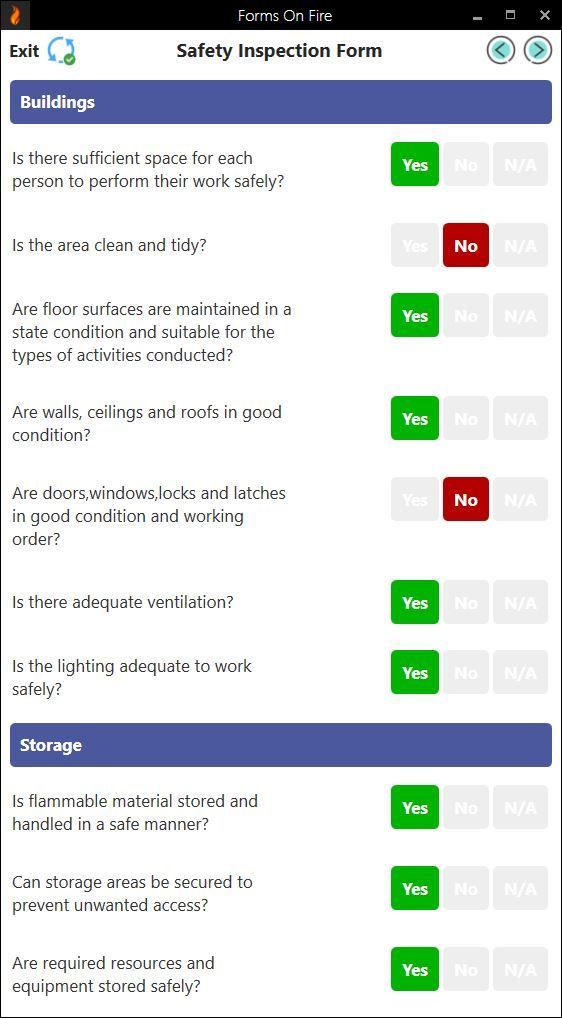

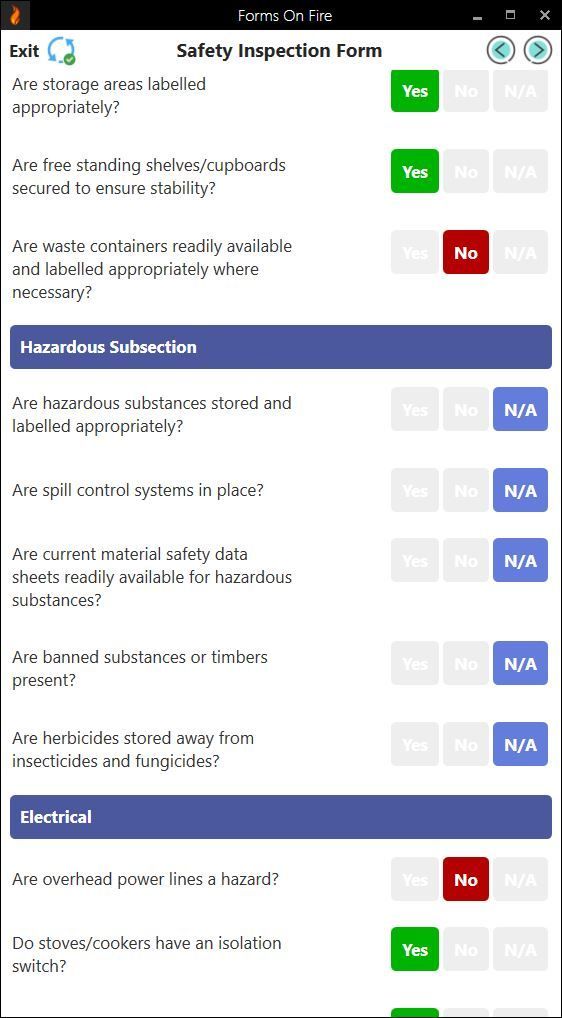

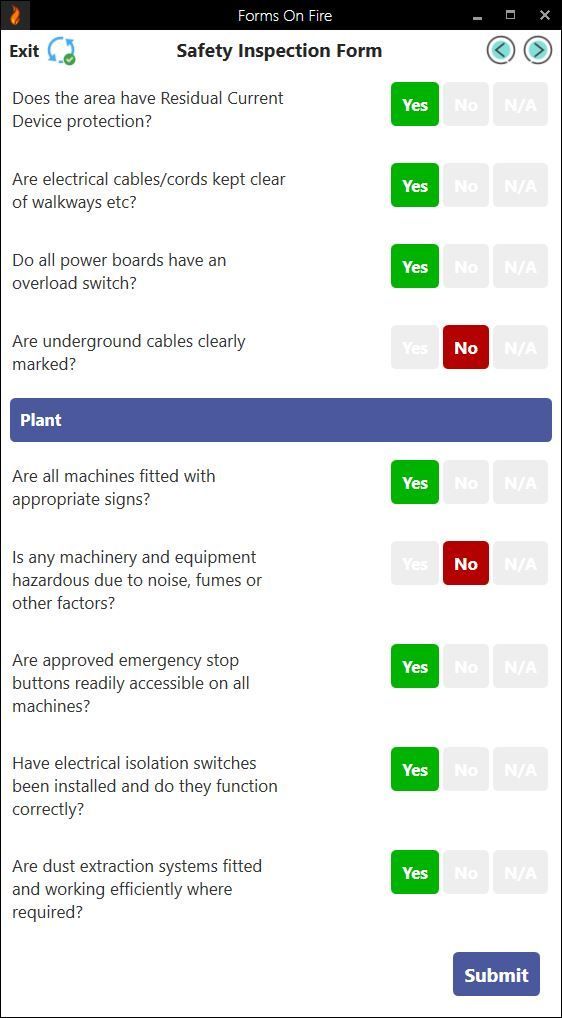

Below is an example of a detailed workplace safety inspection checklist some of our clients use to make safety inspections easier for their safety teams, as well as simplify compliance tracking for safety managers.

If you look closely at the form, you can see that it contains multiple sections like Buildings, Storage, Hazardous Subsection, Electrical, and Plant, each with related safety checks. This helps you work through comprehensive inspections without missing critical areas.

The form uses simple Yes - No - N/A buttons for quick responses — making it easy to complete inspections efficiently while maintaining thorough documentation of safety conditions.

A sample of a health and safety checklist

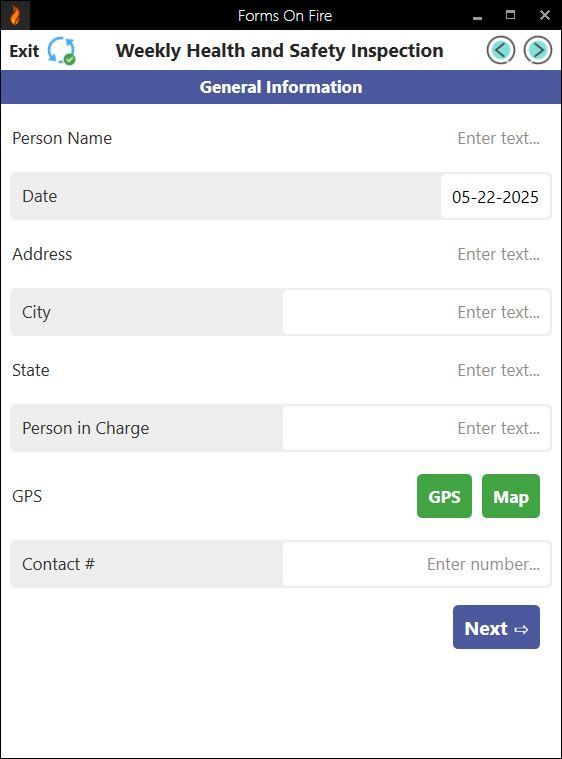

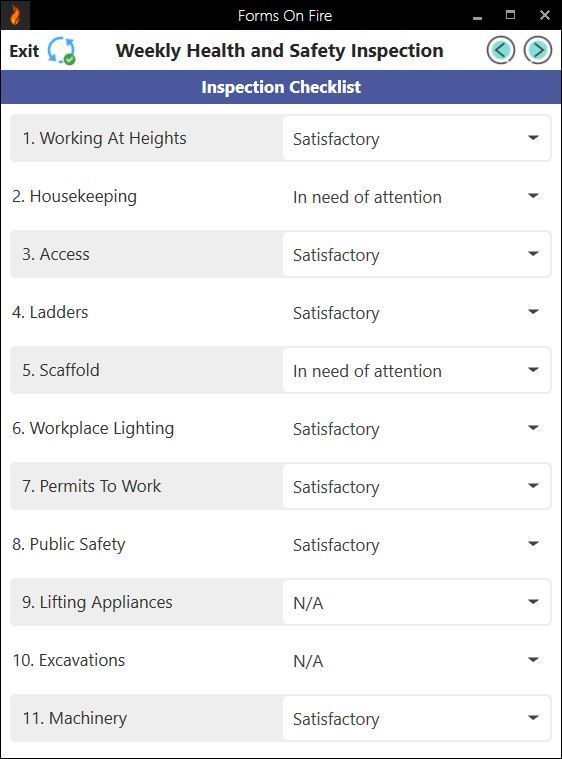

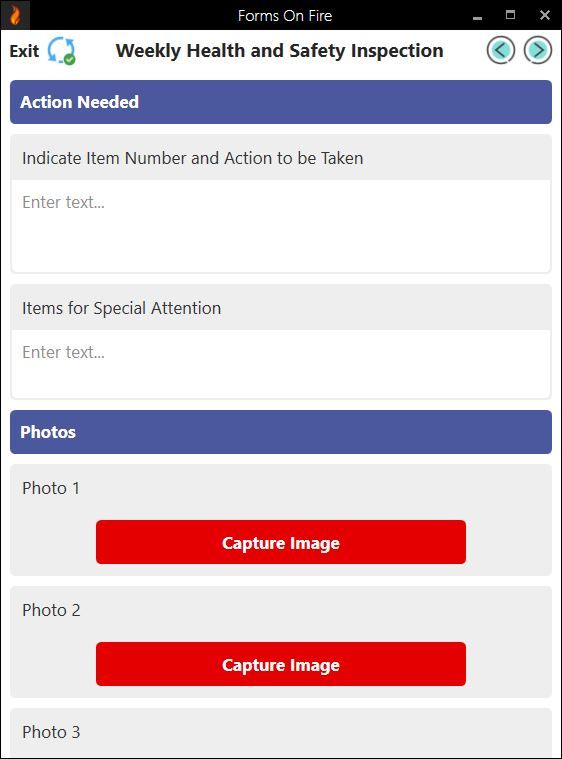

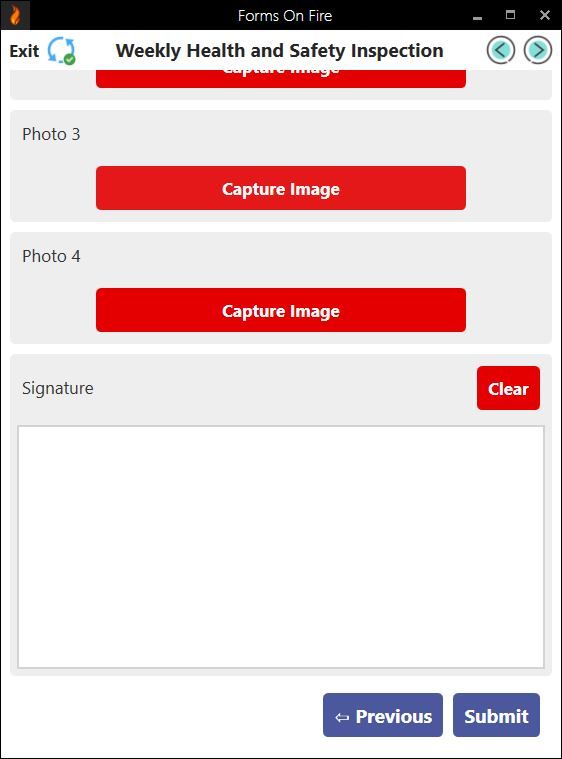

Below is an example of a detailed weekly health and safety checklist some of our clients use to make reporting easier for their construction crews, as well as simplify tracking for safety managers.

This template highlights three helpful features:

- Customizable fields that allow you to tailor dropdown menus, text areas, and input types to match your specific safety requirements.

- Digital signatures for secure sign-offs and compliance documentation.

- Integration capabilities with mobile devices that enable seamless data collection, photo capture, and GPS tracking directly from smartphones or tablets.

Tips for conducting effective safety inspections

Conducting thorough safety inspections requires more than just having the right checklist:

- Consistency is key: Sporadic or irregular inspections can miss developing hazards and send the wrong message about safety priorities. Establish a routine inspection schedule and stick to it, whether that's daily walkthroughs, weekly departmental checks, or monthly comprehensive audits.

- Training: Ensure that personnel conducting inspections are adequately trained. They need to know what to look for, how to identify potential hazards, and understand the proper procedures for documenting findings.

- Documentation: Keep detailed records of inspections, findings, and corrective actions taken. If you are using digital forms, the inspection reports should be saved automatically.

- Engagement: Workers on the front lines often spot safety issues before they become serious problems. Create an environment where employees feel comfortable reporting concerns and actively participate in the inspection process.

Digitize your safety inspections with Forms On Fire

Digital checklists allow you to collect real-time data, making it easy to identify and address safety issues on the spot. Plus, you can update the checklist with just a few clicks — no need to reprint those cumbersome forms!

With all your records in one centralized location:

- You gain a clear and comprehensive view of safety trends throughout your organization.

- You can pull up historical records quickly in preparation for or during audits.

- You can expand the system to send reminders and ensure proper follow-up on identified issues.

- You can finally stop worrying about misplaced paper reports or finding the spreadsheet with the latest updates.

Here’s how you can get started:

- Start a free trial of Forms On Fire: Sign up to explore our template library.

- Find the template: Browse the available templates. Type “safety inspection” in the search bar to find relevant templates.

- Customize the template: If needed, modify fields to match your workflow, team requirements, or safety policies. You can also tweak the design to align with your branding.

- Test the report: Share it with your team for feedback and make any necessary adjustments before rolling it out.

Once you experience how much more efficient and thorough safety inspections become when using digital forms, you'll never want to go back to paper checklists and clipboards.