Commercial HVAC Maintenance Checklist Template

It's July, 95 degrees outside, and your building's AC just quit. Three hundred uncomfortable employees, one very angry facilities director, and an emergency repair bill that's breaking the budget.

HVAC systems run fine until they don't. Then they fail spectacularly, seemingly at the worst possible moment. The good news is that it doesn’t require that much preventive maintenance to prevent that.

Start a free trial of Forms On Fire and get a monthly HVAC maintenance checklist template your technicians can follow from their phone or tablet to keep systems running and catch problems early.

Alternatively, if you are looking to build such a checklist from scratch, this article will cover maintenance schedules, seasonal prep differences, equipment-specific requirements, and practical tips to streamline the whole process.

How often should commercial HVAC systems be serviced?

This really depends on your system and setup. But most commercial HVAC equipment follows a predictable maintenance rhythm.

- Monthly: Change or clean filters, especially if you're running the system constantly or you're in a dusty environment. Some high-traffic buildings need this more often.

- Quarterly: Check refrigerant levels, inspect belts and pulleys, clean condensate drains, and verify thermostat accuracy. This catches small problems before they become expensive ones.

- Semi-annual: Do this before the cooling season and again before the heating season. Clean coils, lubricate moving parts, test safety controls, and make sure everything's ready for the workload ahead.

- Annual: Full system inspection by a qualified technician — checking electrical connections, testing capacitors, measuring airflow, inspecting ductwork, and verifying the system is running at peak efficiency.

Now, those are the baselines. Your actual schedule depends on a few factors:

- Building size and usage: A 24/7 manufacturing facility with a lot of dust and other debris puts way more stress on HVAC equipment than a commercial office that's empty on weekends.

- Climate: Systems in Arizona run cooling almost year-round. Equipment in Minnesota works overtime during winter. If your HVAC is running hard for extended periods, bump up your maintenance frequency.

- Equipment age: Older systems need more frequent checkups. A 15-year-old unit that's been limping along needs more frequent inspections than brand-new equipment.

- Indoor air quality needs: Hospitals, labs, and food processing facilities can't mess around with air quality. These environments often require monthly inspections and more aggressive filter schedules.

Follow manufacturer recommendations as your starting point, then adjust based on how your system actually performs and any operational or regulatory requirements.

What is typically included in an HVAC maintenance checklist

A good HVAC maintenance checklist isn't just a simple list to check off and set aside. Instead, it’s a well-organized record that notes what you’ve inspected, what you’ve discovered, and what needs your attention. Using digital checklists makes this process even smoother.

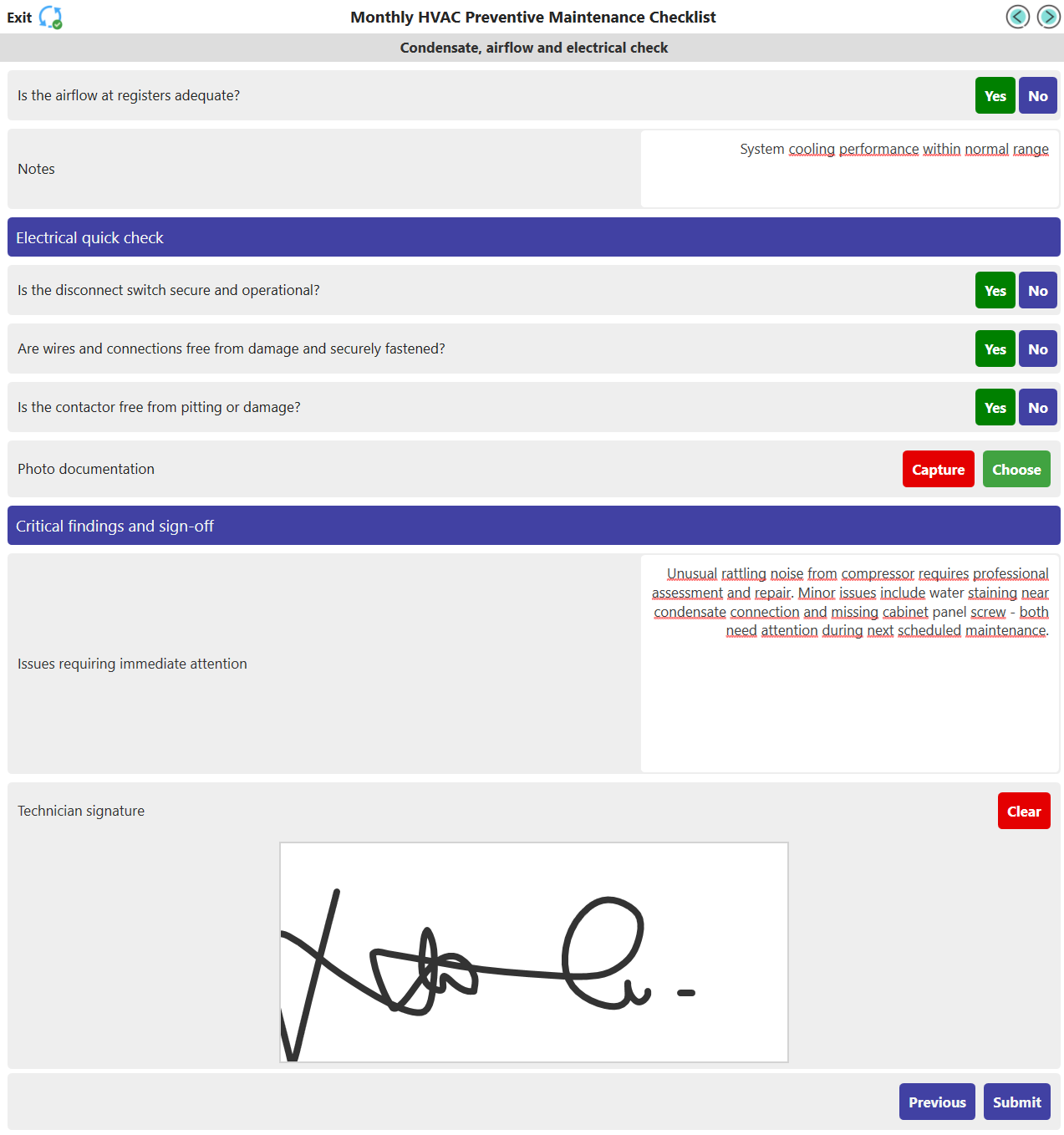

Here's what a comprehensive digital HVAC maintenance checklist should include:

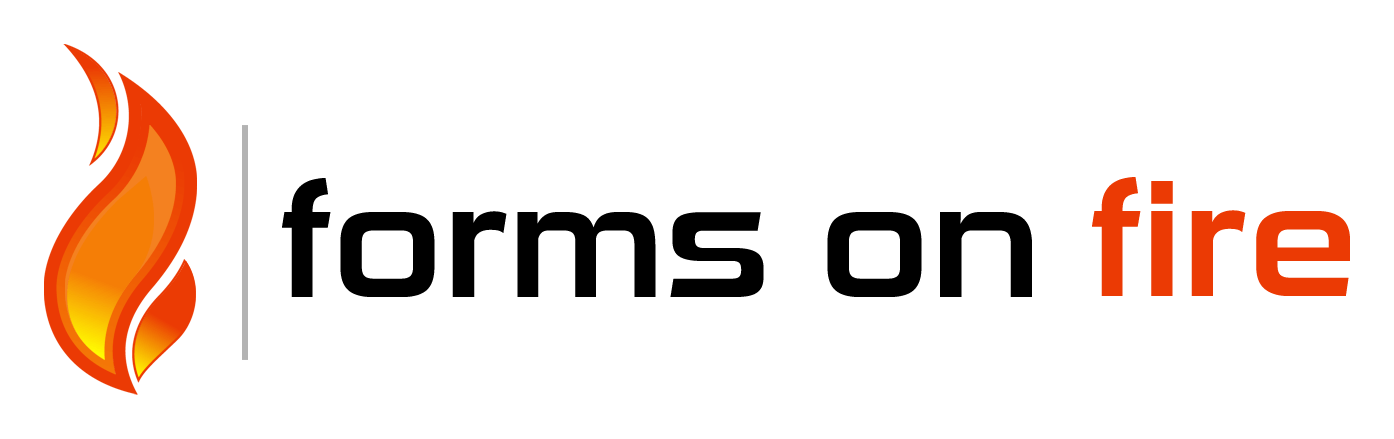

- Contact info and job details: Building name, technician name, date, equipment ID/location, and system type (rooftop unit, chiller, heat pump, etc.).

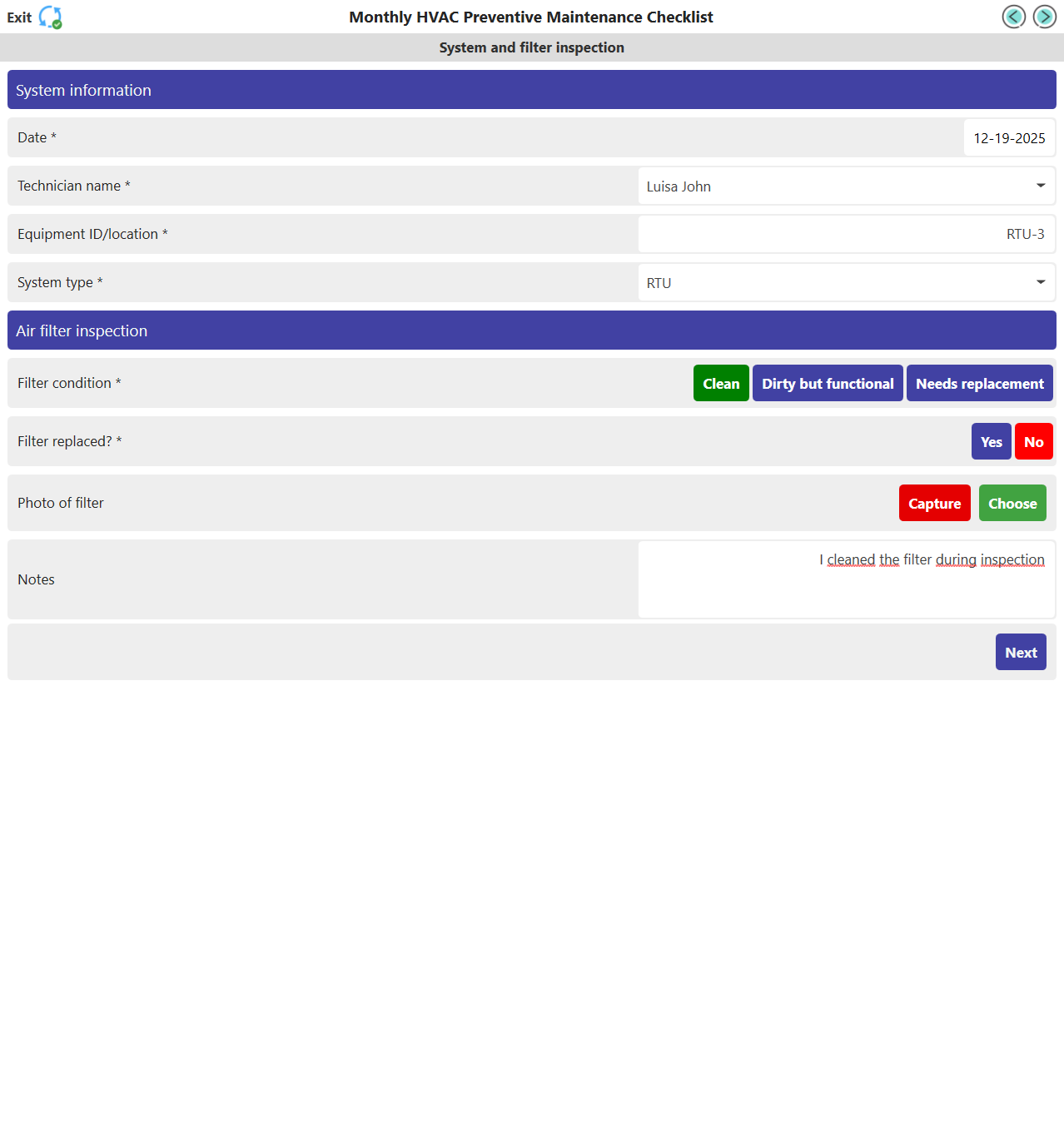

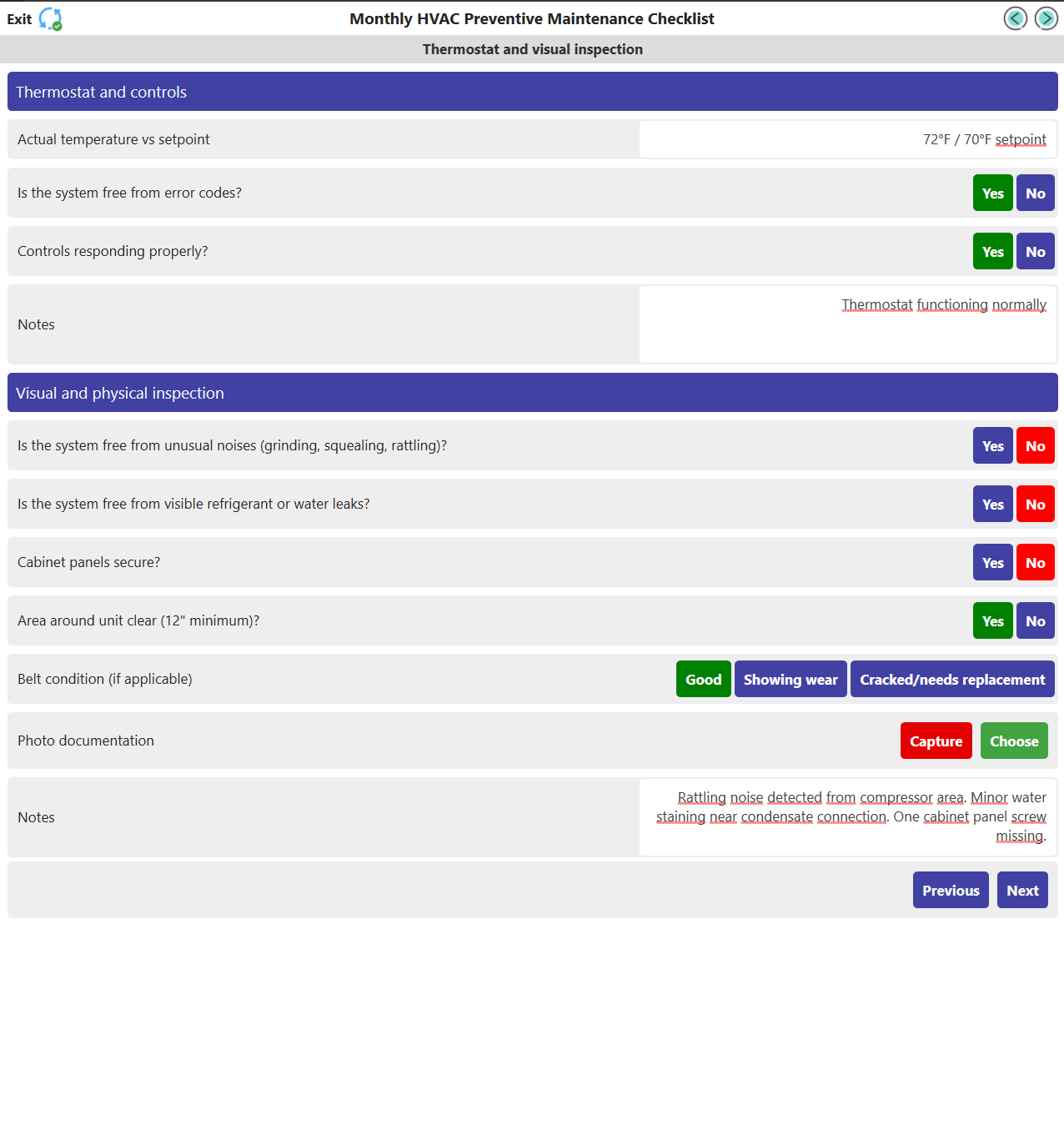

- Task-based inspection sections: Air filters, thermostat and controls, visual and physical inspection, condensate system, airflow and performance, electrical components; each with yes/no questions, dropdown menus, and measurement fields.

- Photo and video capture fields: Built-in spots to snap photos of dirty filters, damaged belts, corroded components, or anything else that needs visual documentation.

- Notes fields for each section: Room for technicians to add context that dropdown menus can't capture, like "Belt showing wear but functional, replace at next quarterly service."

- Critical findings and sign-off: Summary field for issues requiring immediate attention, plus digital signature capture.

Now, the exact tasks on your checklist depend on what you're actually maintaining. A 24/7 manufacturing plant running equipment hard will have way more detailed checks than a small office building that shuts down on weekends. Start with a general template, then customize it to match your equipment, your schedule, and your facility's reality.

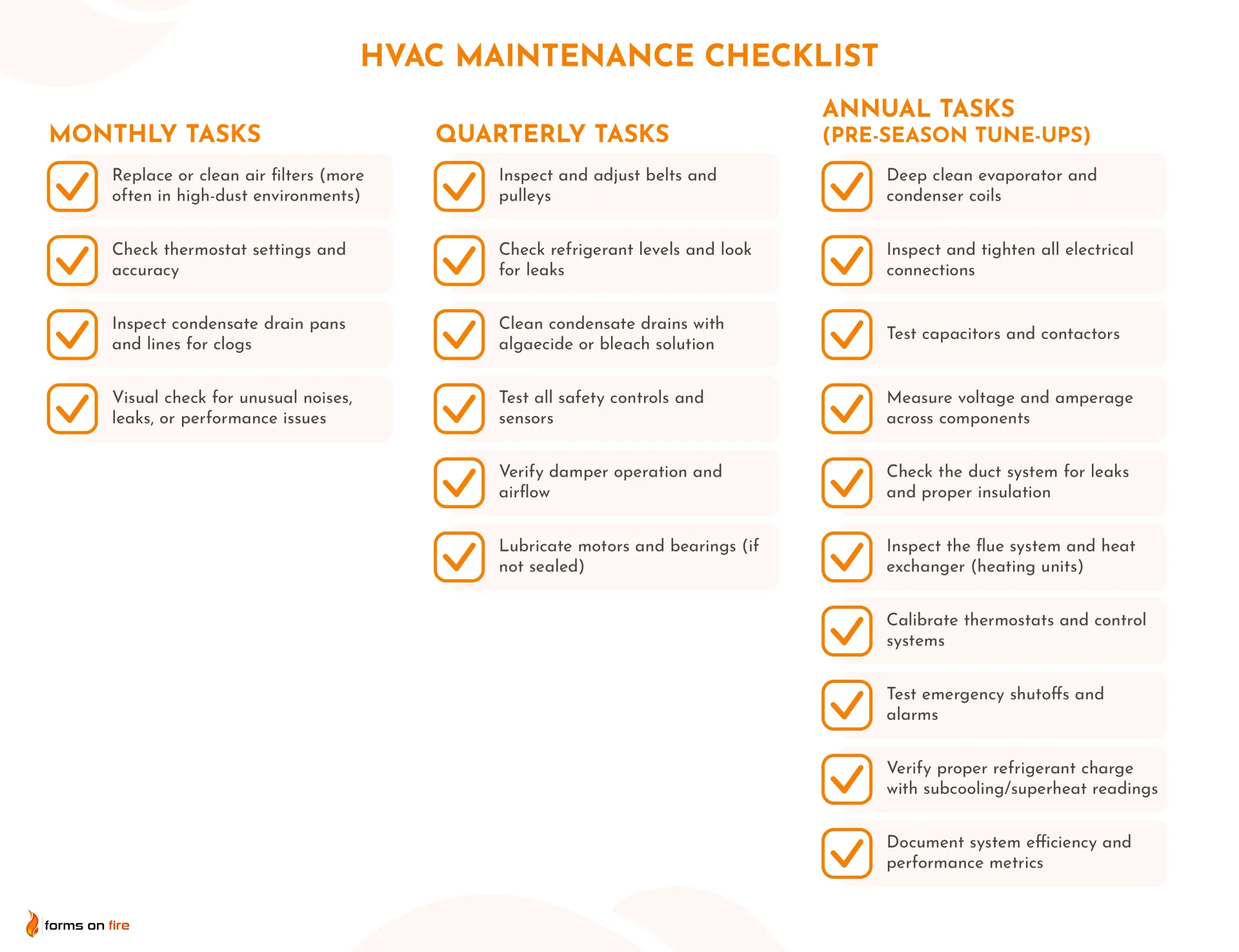

Monthly vs Quarterly vs Annual tasks

A commercial HVAC system can be pretty complex. So not all maintenance tasks happen on the same schedule. Some parts need attention every month, others can wait until quarterly checkups, and a few only make sense during your big annual tune-up. Here's a rough breakdown:

Monthly tasks:

- Replace or clean air filters (more often in high-dust environments)

- Check thermostat settings and accuracy

- Inspect condensate drain pans and lines for clogs

- Visual check for unusual noises, leaks, or performance issues

Quarterly tasks:

- Inspect and adjust belts and pulleys

- Check refrigerant levels and look for leaks

- Clean condensate drains with algaecide or bleach solution

- Test all safety controls and sensors

- Verify damper operation and airflow

- Lubricate motors and bearings (if not sealed)

Annual tasks (pre-season tune-ups):

- Deep clean evaporator and condenser coils

- Inspect and tighten all electrical connections

- Test capacitors and contactors

- Measure voltage and amperage across components

- Check the duct system for leaks and proper insulation

- Inspect the flue system and heat exchanger (heating units)

- Calibrate thermostats and control systems

- Test emergency shutoffs and alarms

- Verify proper refrigerant charge with subcooling/superheat readings

- Document system efficiency and performance metrics

Pro tip: Bundle your quarterly tasks with monthly checks when it makes sense. If you're already up on the roof checking filters, take an extra few minutes to look at belts and drains. Efficiency matters when you're maintaining multiple units.

Summer vs winter HVAC PM checklist

Your HVAC system works differently depending on the season, which means your maintenance focus shifts, too. Here's what to prioritize before cooling season kicks in versus what matters when you're prepping for heating:

| Spring/summer (cooling season prep) | Fall/winter (heating season prep) |

|---|---|

| Clean condenser coils: they collect dirt, pollen, and debris over winter | Inspect heat exchangers for cracks or corrosion (carbon monoxide risk) |

| Check refrigerant levels and look for leaks before the AC runs full-time | Test ignition systems and burners in gas furnaces |

| Test compressor operation and measure amp draw | Check flue and venting systems for blockages or leaks |

| Inspect condensate drain lines and pans (clogs cause water damage fast in summer) | Verify all heating modes and stages are working |

| Verify all cooling modes and stages are working | Inspect and test limit switches and safety controls |

| Clear vegetation and debris around outdoor units for proper airflow | Check gas pressure and combustion efficiency |

| Test economizer dampers if your system uses outside air for cooling | Lubricate blower motors before extended heating runs |

| Test humidification systems if equipped |

Some tasks overlap: filter changes, belt inspections, and electrical connections matter year-round. But catch the season-specific stuff before you actually need that system running at full capacity, or you're fixing problems in 95-degree heat or freezing temps when everyone's already uncomfortable.

Type of HVAC system

Not all HVAC systems are built the same, and they definitely don't maintain the same. What works for a rooftop unit won't fly for a chiller plant. Here's what you need to know about the most common commercial systems:

- Rooftop units (RTUs): These sit exposed to weather, so coils get dirty fast, and components wear harder. Focus on cleaning coils in spring and fall, checking refrigerant quarterly, and inspecting gas burners annually. RTUs take a beating from sun, rain, and debris; expect more frequent belt replacements and motor issues than indoor equipment.

- Split systems: The condenser lives outside, the air handler inside. To maintain the condenser, clean the condenser coils, check the refrigerant, clear debris, and check the refrigerant lines annually for leaks; pinhole leaks are common and can be expensive if you miss them. For the inside unit, change filters monthly, inspect blower assemblies, and clean drain pans.

- Chillers (water-cooled and air-cooled): Water-cooled chillers need regular water treatment to prevent scale and corrosion. Test water quality monthly, clean tubes annually, and monitor compressor oil. Air-cooled chillers skip water treatment but need aggressive coil cleaning — dirty coils kill efficiency. Both need annual refrigerant analysis, oil changes, and compressor vibration monitoring.

- Variable refrigerant flow (VRF) systems: Efficient but finicky. Each indoor unit has its own filter and drain, so you're multiplying monthly tasks. Extensive refrigerant piping makes leak detection critical — use electronic detectors during annual inspections. VRF relies heavily on sensors and controls, so calibrating thermistors and checking unit communication matters as much as mechanical work.

- Boilers and radiant heating: Boilers need annual combustion testing; check CO levels, flue temps, and burner efficiency. Inspect heat exchangers for cracks or corrosion. Water-side maintenance includes pH testing, scale treatment, and bleeding air from the system. Test circulation pumps and zone valves to catch stuck or failed components.

- Heat pumps: These are air conditioners that reverse. Do standard AC maintenance — coils, refrigerant, filters — plus check reversing valve operation and defrost cycles. Heat pumps work harder in heating mode than standard AC, so expect more compressor wear. Test both heating and cooling modes during seasonal prep.

- Dedicated outdoor air systems (DOAS): These handle ventilation separately. Filters need monthly attention because they're processing 100% outside air, which is dirtier than recirculated air. Energy recovery wheels need to be cleaned quarterly because they clog with dust and pollen. Check dampers and controls closely, since DOAS units coordinate with your main HVAC system.

Equipment type dictates your maintenance plan. Know what you've got, follow the manufacturer specs, and adjust frequency based on how hard the system works.

An example of a monthly HVAC preventive maintenance checklist template

Monthly maintenance catches the small stuff before it becomes expensive. This template covers the basics that apply to most commercial HVAC systems — filters, thermostats, drains, and quick visual checks. Use it as your starting point, then adjust based on your specific equipment and building type.

Build this into your overall maintenance schedule. Monthly checks work best when they're part of a bigger plan that includes quarterly and annual tasks. Don't treat this as a standalone — it's one piece of keeping your HVAC systems running reliably.

Also, monthly inspections will surface problems. A failing capacitor costs $150 to replace now or $3,000 when it takes out the compressor. Set aside a budget based on equipment age and condition so you're ready when inspection reports come back with issues.

Tips to streamline commercial HVAC maintenance

HVAC maintenance doesn't have to be a chaotic scramble of clipboards, missed appointments, and systems that break down right before a heat wave. A few smart changes to how you approach maintenance make the whole operation run smoother and catch problems before they cost you money:

- Build a master schedule and stick to it: Create a calendar that maps out every piece of equipment, what needs to happen when, and who's responsible. Monthly filter changes, quarterly belt checks, annual tune-ups — get it all on the schedule so nothing slips through the cracks.

- Use digital checklists: Paper gets lost, wet, or left in someone's truck. Technicians’ handwriting can be hard to decipher. Digital forms keep everything in one place, let you snap photos of problems, and automatically timestamp inspections. Plus, finding records is so much faster and easier.

- Train multiple people on basic tasks: Don't make one person the bottleneck. If only one tech knows how to change filters or check refrigerant levels, you're stuck when they're out sick or on vacation. Cross-train your team so routine maintenance keeps happening regardless of who's available.

- Keep parts inventory for common failures: Stock the stuff that breaks regularly — belts, filters, capacitors, contactors. When a belt snaps, you want to grab one from inventory, not wait three days for shipping while the system runs inefficiently. Track what fails most often and keep those parts on hand.

- Set up alerts for critical metrics: Modern building automation systems can notify you when something's off — refrigerant pressure drops, temperature spikes, airflow decreases.

- Bundle tasks by location and frequency: If you've got multiple rooftop units, you might want to do all the monthly checks in one trip instead of visiting the roof five times. When you're maintaining dozens of units across multiple facilities, smart scheduling saves hours every month.

Build handy digital checklists with Forms On Fire

Paper checklists work until they don't…sort of like running an HVAC system without maintenance. Eventually, something breaks down.

Forms On Fire is a mobile-first platform built for field teams who need to capture data on-site, stay organized, and actually use the information they collect.

Here's why it works for commercial HVAC maintenance:

- Built for field teams: Your techs are on rooftops and in mechanical rooms, not at desks. Forms On Fire runs on phones and tablets, so inspections happen where the work gets done.

- Works online and offline: Basements and equipment rooms have a spotty signal. Fill out inspections offline; everything syncs when you're back online. No lost data, no duplicate entry.

- Capture photos, videos, and notes: Snap a photo of that cracked heat exchanger or corroded coil right in the form. Later, when someone asks "how bad was it?", you've got proof.

- Digital signatures: Get sign-offs from facility managers or document completed work. Everything stays attached to the proper record.

- Automated reporting: Data generates reports you can email to building managers or export for compliance. Spot patterns like belts failing every quarter across multiple units.

- AI assistant: Describe what you need — "quarterly HVAC checklist for rooftop units" — and the AI builds it. Upload an existing paper form, and it converts to digital.

- Free support that actually helps: Need conditional logic or automated alerts? Support will help you build it — not just troubleshooting, but actual form design help.

Start your free trial and grab our HVAC maintenance checklist template. Customize it for your equipment, try it on a few units, then roll it out organization-wide.