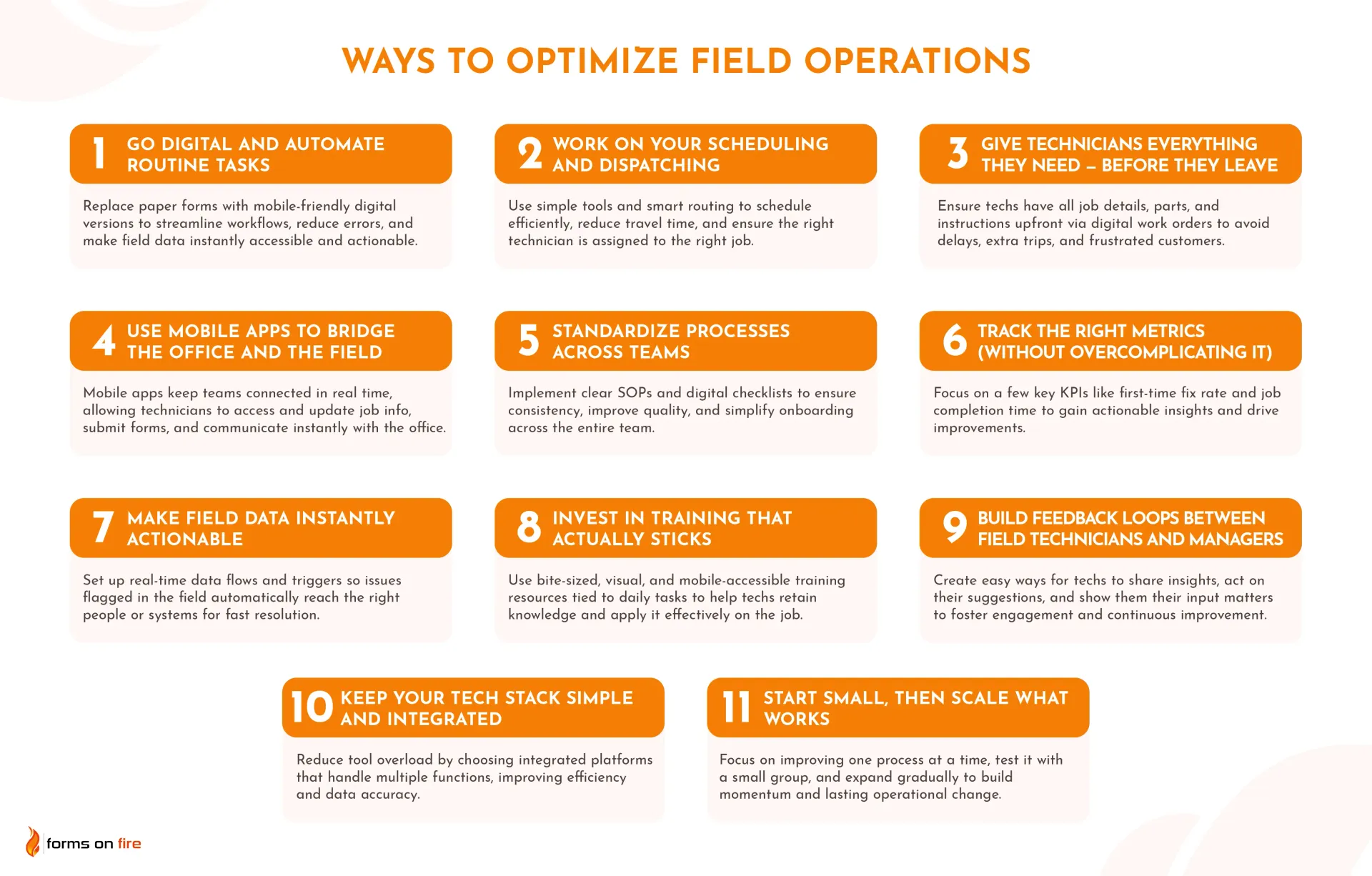

11 Tips and Strategies to Optimize Field Operations

If you manage a field service team, you already know how quickly things can go off the rails. A missed work order here, a late arrival there — and suddenly, your whole schedule is upside down.

Meanwhile, the office is chasing down paperwork, techs are calling in for missing info, and clients are getting impatient.

The truth is, most field service issues don’t come from one big failure — they come from a bunch of small inefficiencies that pile up over time. The good news? You can fix them. And you don’t need to rip everything out and start from scratch to do it.

In this article, we’re walking through 11 practical ways to streamline your field operations that will help your team move faster, communicate better, and deliver more consistent service.

1. Go digital and automate routine tasks

Every time your techs have to fill out a form by hand, then drive it back to the office or scan and email it in, you’re losing time — and probably missing details along the way. It also creates bottlenecks for everyone waiting on that info to move the job forward.

It’s time to digitize those paper forms. Mobile-friendly forms and automated workflows not only reduce admin time but also make life easier for field teams. Plus, going digital makes the data clean, fast to review, and easy to store.

Digital forms are much easier to implement than you think. Here's where you can start:

- Work orders: Digital work orders let techs receive assignments, access job details, and mark tasks as complete — all from their phones or tablets. No more miscommunication or delays from paperwork getting lost.

- Inspections and checklists: Pre-built inspection forms with required fields and conditional logic ensure that every job is completed to the required standard.

- Reporting and documentation: Photos, GPS stamps, timestamps, and comments can all be captured on-site. That means real-time updates to the back office and accurate documentation for compliance and billing.

- Collecting signatures and approvals: Digital signatures can be collected instantly — no clipboards or follow-up visits. Great for customer approvals, confirming completed work, or internal sign-offs.

Modern mobile form software, like Forms On Fire, makes this easy through pre-built templates and drag-and-drop functionality. When a form is ready, just share it with your team, who can access it on any mobile device.

2. Work on your scheduling and dispatching

Efficient scheduling is the backbone of productive field service management. But if you're still juggling jobs with spreadsheets, sticky notes, or last-minute phone calls, you're leaving time (and money) on the table.

Here are six practical ways to tighten up your scheduling and dispatching process:

- Use simple scheduling tools: Don’t overcomplicate it. You don’t need enterprise software to start — even lightweight tools with drag-and-drop calendars, technician availability, and mobile notifications can make a big difference. Bonus if they sync with your digital forms and CRM.

- Group jobs by location: Cut down drive time by assigning nearby jobs to the same tech or scheduling them back-to-back. Even a small reduction in windshield time each day adds up to serious savings over a year.

- Optimize routes: Use tools that factor in traffic, distance, and appointment windows to recommend the most efficient route. Some field service platforms and even basic route planning apps can do this automatically.

- Match skills to jobs: Make sure you’re sending the right person for the job, not just the closest one. Tag technicians by skill, certification, or tools they carry, so dispatchers can assign more accurately.

- Fill scheduling gaps smartly: Keep an eye out for cancellations or gaps in the schedule. Use those windows for shorter jobs or follow-ups nearby — a quick win for productivity.

- Give techs real-time access: Let field staff see their schedules, updates, and job details on their phones. If plans shift during the day, push changes instantly instead of calling or texting (and hoping they see it in time).

The right tools and a few process tweaks can dramatically improve how you assign and manage fieldwork, especially as your team grows.

3. Give technicians everything they need — before they leave

Few things kill productivity faster than a tech showing up to a job without the right info, tools, or parts. They get there, poke around for a bit, realize they’re missing something, and now it’s back to the warehouse or a phone call to the office. Meanwhile, the customer’s getting frustrated, and you’re burning time and fuel for no reason.

Most of these headaches are completely avoidable — you just need to ensure your team has everything they need before they leave for the job.

Include the details that actually matter:

- What is the issue?

- What parts do they need?

- How to access the site?

- Who to talk to when they get there?

If there’s service history, share it — knowing what’s been done before can save a ton of guesswork. Got a photo of the setup or equipment? Even better. The more context, the more confident and prepared your tech will be when they walk in.

And when all of that lives in a digital work order they can pull up on their phone or tablet, it’s a game-changer. No digging through old emails or calling dispatch for missing info. Just a smooth, efficient visit — and ideally, a job done right the first time.

4. Use mobile apps to bridge the office and the field

If there’s one thing that can quietly wreck your field operations, it’s miscommunication. A tech shows up at the wrong time, the office doesn’t get an update, a job gets missed — and suddenly, you’re dealing with double work and unhappy customers.

That’s where mobile apps come in. They’re one of the simplest, most effective ways to keep your field team and office staff on the same page, in real time.

With the right app, technicians can receive work orders instantly, check in and out of jobs, submit forms, upload photos, and even chat with the office if something changes.

And the best part? You don’t need a massive software overhaul to get started. You can create a few digital forms, connect them to the same database, and you have a lightweight app that handles scheduling, work order details, and reporting.

The goal isn’t to overwhelm your team with tech — it’s to make their day smoother and give everyone better visibility into what’s happening in the field.

5. Standardize processes across teams

If every technician has their own way of doing things, you'll get mixed results. One tech might take detailed notes and photos, while another barely checks the boxes. Some might follow safety procedures to the letter, while others might skip steps to save time.

It’s not about bad intentions — it’s just what happens when there’s no standard in place.

That’s why creating clear, consistent processes is so important. The easiest way to do that is to build digital checklists or standard operating procedures (SOPs) for the key parts of your operation: how to document a job, how to perform inspections, or how to troubleshoot a specific piece of equipment.

This also makes onboarding way easier. New hires don’t have to shadow someone and hope they pick things up quickly; they’ve got clear steps to follow from day one.

Here are a few additional ideas to reinforce standardization:

- Use pre-filled templates for forms and reports.

- Make certain fields required so nothing important gets skipped.

- Set up automated reminders for follow-ups or safety checks.

- Encourage feedback from the field — your techs will often have great suggestions for tightening things up.

This is one of the easiest ways to level up your operations without adding more overhead.

6. Track the right metrics (without overcomplicating it)

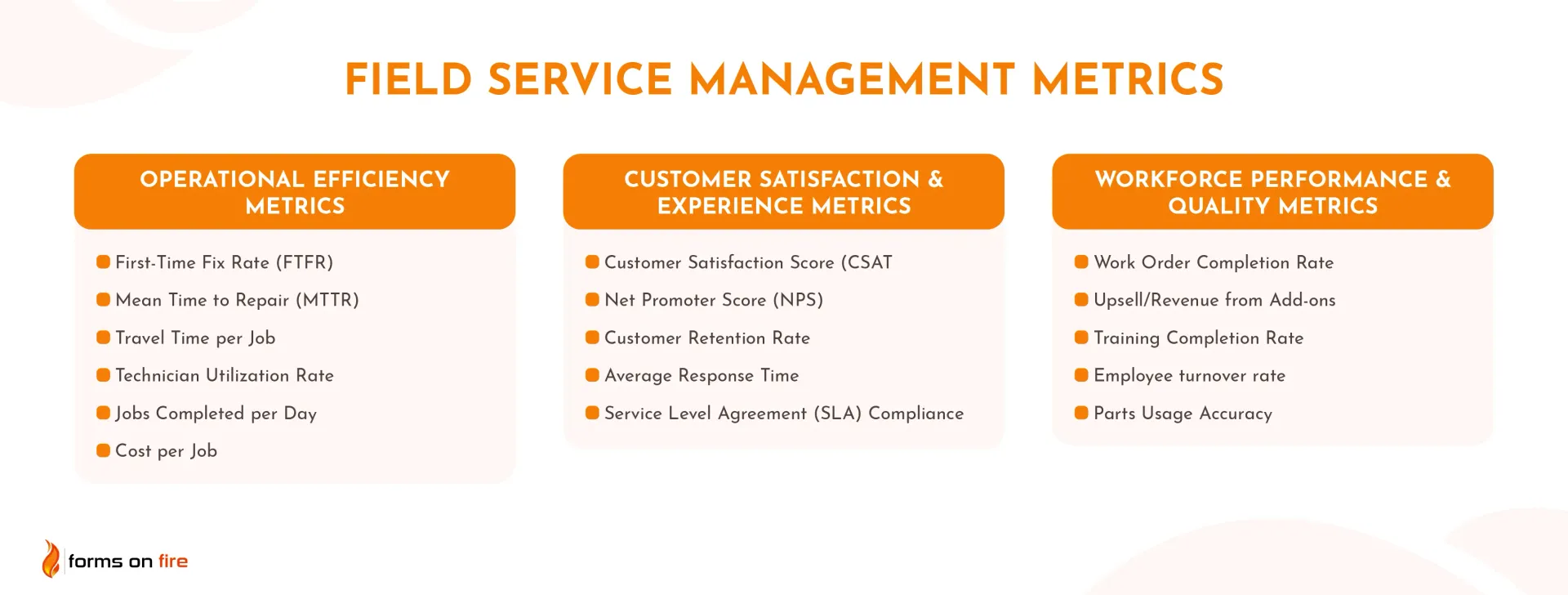

You can’t improve what you don’t measure — but let’s be honest, tracking everything quickly becomes a mess. Endless reports, charts, and numbers that no one looks at or uses. Start small and focus on the field service metrics that actually move the needle for your team.

Start with just a few core KPIs that give you a clear picture of how your field operations are performing:

- First-time fix rate: Are your techs resolving issues on the first visit, or are repeat trips eating up time and budget?

- Average job completion time: How long does it take to complete a typical service call from arrival to wrap-up?

- Jobs completed per day: Is your team operating at full capacity, or is there room for better scheduling?

- Customer satisfaction: A quick post-job survey can give you instant insight into how your service is perceived.

Once you’ve got a good process for collecting and reviewing those, you can build from there.

For example, if your first-time fix rate is low, you might start tracking parts availability or how often techs arrive on-site without enough information. That will lead you to deeper process improvements, like better pre-job checklists or smarter inventory management.

7. Make field data instantly actionable

Collecting data is one thing — using it is another. If job details, inspection results, or issue reports are stuck on paper, sitting in someone’s inbox, or waiting to be typed into a spreadsheet later… you’ve already lost valuable time. By the time someone finally sees it, the moment to act may have passed.

Make sure the data your team collects in the field flows instantly to the right place — whether that’s a supervisor who needs to approve something, a live dashboard that tracks performance, or your CRM where it becomes part of the customer’s record.

One simple way to do this is to set up automated triggers. For example, let’s say an inspection form includes a question about equipment damage. If the tech selects “yes,” the system could instantly:

- Notify the operations manager

- Create a follow-up task or work order

- Flag the equipment as “out of service” in your asset tracking system.

The same approach applies to job completions, failed quality checks, overdue forms, and other tasks. The goal is to ensure nothing falls through the cracks and that issues are handled sooner rather than later.

8. Invest in training that actually sticks

Throwing your team a stack of manuals or a long PDF and calling it “training” doesn’t cut it. Most of it gets skimmed, forgotten, or ignored completely. And when a tech is standing in front of a customer or troubleshooting a piece of equipment, flipping through a binder isn’t exactly practical.

Training works best when it’s easy to absorb and easy to apply. Try to implement:

- Bite-sized training: Short, focused lessons are easier to remember and way less overwhelming. Frequent, quick demonstrations for a specific task often beat hours-long sessions where everything is crammed together.

- Visualization: Visual instructions stick better than text. Create annotated images and add them to work instructions. Record a quick walkthrough using your phone. No need for fancy production, just clarity.

- Mobile-accessible guides: Give techs access to troubleshooting steps, SOPs, or diagrams right from their phones or tablets. When they hit a snag in the field, they should be able to look up what to do in seconds.

- On-the-job refreshers: Build training into your workflows. For example, link a short video or tip to a checklist step, so techs get a quick reminder right when they need it.

- Peer learning: Encourage experienced techs to share their own tips or common field mistakes. Better yet, task them with creating SOPs and checklists for everyday field tasks.

Training creates efficient techs who make fewer mistakes. Plus, when employees know what they’re doing — and know the company is helping them grow — they’re more likely to stick around.

9. Build feedback loops between field technicians and managers

Your field technicians are the eyes and ears of your operation. They’re out there every day, seeing what’s working, what’s not, and where things could run more smoothly. But if there’s no clear way for them to share that feedback, those valuable insights just disappear.

That’s why it’s so important to create simple, low-effort ways for techs to speak up — and to actually listen when they do.

One easy solution is a short digital feedback form that techs can fill out at the end of a job or at the end of their shift. It could include quick prompts like “Did anything slow you down today?” or “Any suggestions to improve how we handle jobs like this?”

You can also create a running digital “suggestion box” that they can use anytime, without waiting for a formal meeting.

But here’s the key: close the loop. If someone flags a recurring issue or suggests a better way to do something, and you make a change because of it, tell them. It shows their input matters — and that leads to more engagement, better ideas, and a culture of continuous improvement.

Techs want to feel heard, and managers need real insight from the field. A good feedback loop connects the two and drives smarter decisions from the ground up.

10. Keep your tech stack simple and integrated

Technology is supposed to make your life easier. However, if your team is juggling five different apps that don’t talk to each other, you’re not simplifying anything.

When your scheduling tool is separate from your forms app, which is separate from your time tracker, which is separate from your reporting system… guess who ends up stitching it all together? Usually, someone on your admin team — or worse, your field techs.

That’s time wasted, with a lot of room for errors and silos that compromise data accuracy and make tracking KPIs meaningless.

Instead, aim for a lean tech stack that plays well together. Even better, use one platform that can handle multiple functions under one roof. Again, Forms On Fire is a great example — you can build digital forms, automate workflows, and push data straight into other systems you already use, like your CRM, maintenance software, or business intelligence tool.

The fewer tools your team has to juggle — and the better they integrate — the smoother your entire field operation runs.

11. Start small, then scale what works

When you’re looking at your entire field operation, it’s easy to feel like everything needs improvement. But trying to overhaul every process at once leads to chaos, confusion, and burnout. It’s often better to start small.

Pick one process that’s clearly slowing things down — maybe it’s your equipment troubleshooting process, collecting signatures from customers, or how work orders are assigned or closed out. Digitize it. Test it with a few team members. See what works, what doesn’t, and tweak as needed. Once that piece is running smoothly, move on to the next.

This kind of step-by-step improvement is how real progress happens. It’s easier to get team buy-in when they’re not overwhelmed, and you’re more likely to catch small issues before they become big ones.

Plus, momentum builds quickly. Once your team sees how one small change saves time or reduces headaches, they’ll be more open to trying the next one. And before long, those small wins start adding up to a much more efficient, connected, and scalable field operation.

Optimize field service operations with Forms On Fire

Optimizing field service operations isn’t about big, flashy overhauls — it’s more about solving the small, everyday problems that slow your team down. Whether it's lost paperwork, poor communication, inconsistent processes, or clunky tools, every one of those issues can be fixed with smarter systems and better workflows.

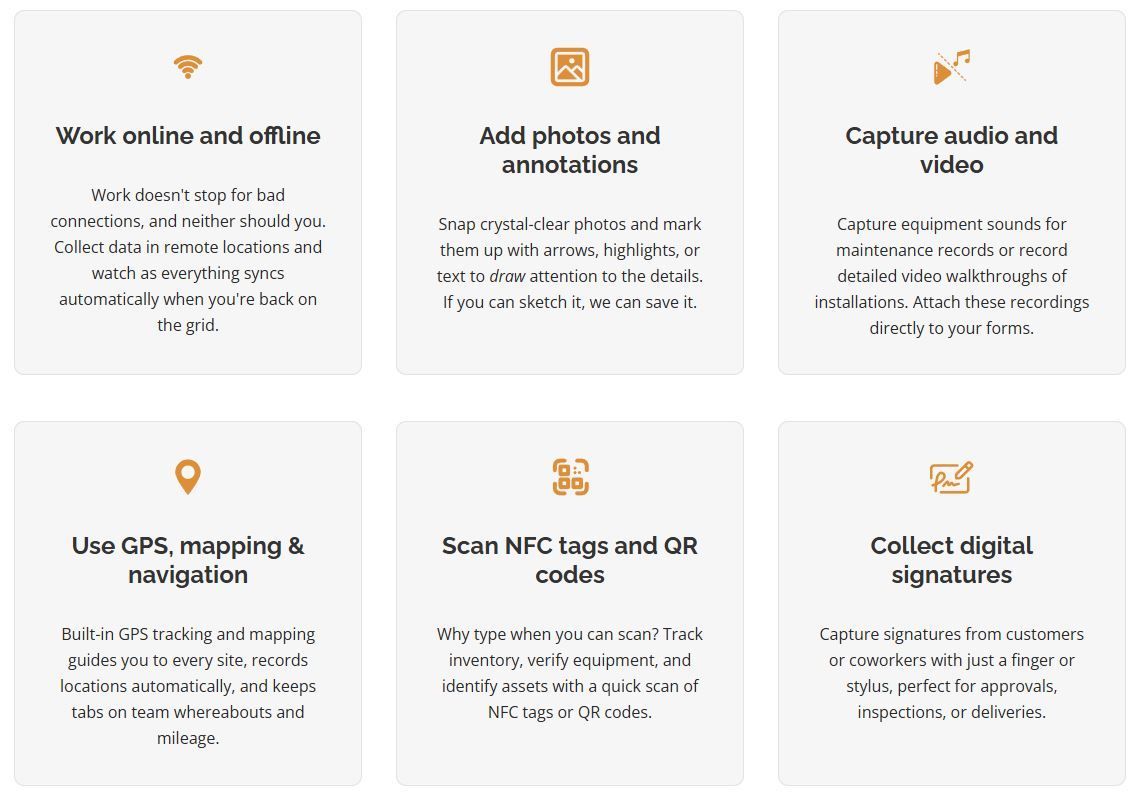

That’s where a platform like Forms On Fire really shines. It’s packed with practical features designed for the realities of field service teams:

You can digitize inspections, automate work orders, standardize checklists, and connect everything to your existing systems. It’s a no-code platform, which means your operations team can create powerful, custom workflows without writing a single line of code.

Your field team gets the information they need to work smarter — while your office team gets real-time visibility into what’s happening out in the field.

Want to see how it all comes together?

Schedule a quick demo and learn how teams use Forms On Fire to optimize field operations.